Another journey in the chemical industry, customers field practice

After many times invitations from customers, our company leader finally arrived, at the A company for on-site inspections and held technical discussions with their principals. From the drawing data to the simulation-modeling situation to the field layout, it took 5 days in total. In-depth on-site discussions will continue in the later period.

Company A is an important large-scale chemical group company in northern China. It has a large-scale factory and a long history. It is well known in the local area and has made very important economic contributions to the local area. With social development and progress, it needs continuous transformation and upgrading. At the same time, competition in similar industries has intensified to improve production efficiency, and automated assembly lines have become a step that factory-type companies must leap. Company A contacted us in many supplier directories. Finally, because Company A believes that another foreign company has a long delivery period, long delivery and transportation time other than us, it also has domestic brands that meet various requirements in our country, so there is no doubt that Company A has done business with us.

Due to the impact of COVID-19, our company leaders and the leaders of Company A contacted on the phone for more than one month, and they discussed the mechanical and layout drawings many times, which enabled Company A to increased trust in our technical capabilities and professionalism. With the improvement of the situation of COVID-19 in some areas and the strong invitation of the other party’s leaders many times, our company leaders conducted on-site inspections of the customer’s factory for 5 days, measured and analyzed, and gave questions on the customer’s questions a practical solution.

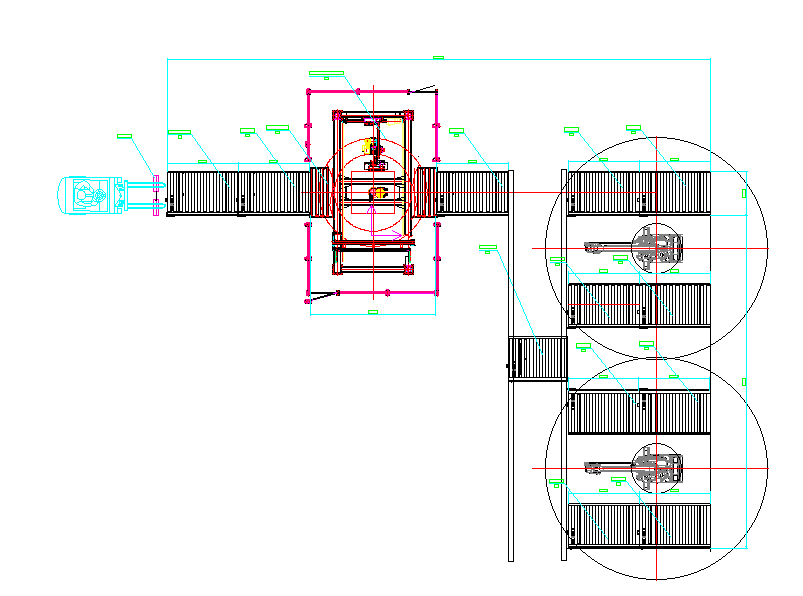

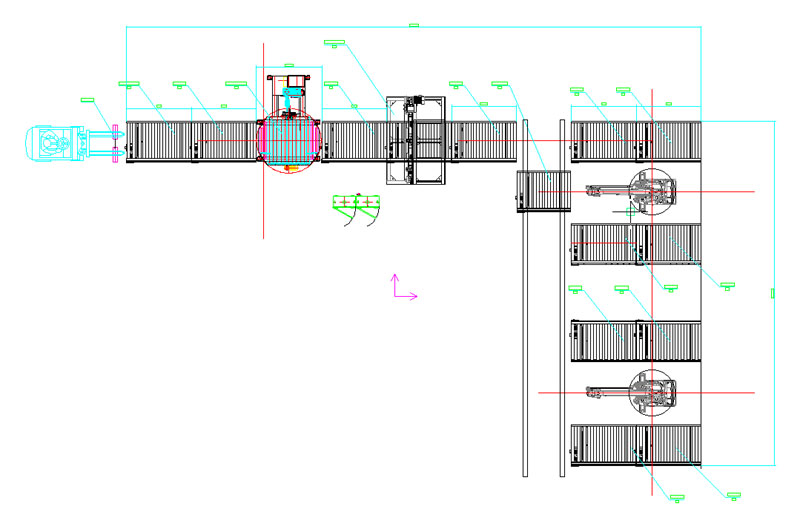

According to the actual situation of company A, we propose a complete packing system. Starting from the conveyor line of the goods, the machine developed by us will pack the goods on the conveyor line, and then the mobile carriers will be distributed to different conveyor lines. The process does not require labor, fully automated packing, and only requires staff to supervise the process to check the packaging of goods and the operation of the packaging line

Our packing system itself has experience in cooperating with the chemical industry. Therefore, cooperating with Company A is familiar and has very high practical significance. Because the company has high requirements for the packaging of the goods, the packaging materials used by our company can meet the packaging needs of its goods, dust-proof, moisture-proof, anti-corrosion, and have a very good appearance. Because customers want to reduce costs, we also provide reusable packaging bags based on our years of experience, helping customers solve problems that have plagued them for many years.

Through communication with Company A, we have established a solid foundation for mutual trust. We will follow up the various procedures of this cooperation. The company has invited us to discuss cooperation matters again. Of course, as a veteran manufacturer with more than 20 years of existence, solving problems for customers is not worth mentioning. Even without cooperation in the end, we believe that customers highly recognize and agree with our brand and technology.

TEL: +86-531-84992618

Email: export@joompac.com

ADD: No. 688, Chunhui Road, high tech Zone, Jinan City, Shandong Province (within the Chinese Academy of Railway Sciences)